Joint forces between PLCopen, OPCF and the OMAC Packaging Workgroup facilitates a standardized and “off the shelf” PackTag data exchange via OPC UA

Overview

The objective of the OMAC Packaging Workgroup (OPW) is to maximize the business value of packaging machinery by improving automation guidelines and standards. This will lead to improved flexibility, improved capability, and reduced system integration costs.

To attain this goal, we work with automation suppliers, OEMs, and trade groups worldwide to encourage their support of the OMAC Packaging Guidelines throughout their products and practices, creating a mutually beneficial environment for the guidelines.

The OMAC Packaging Guidelines make packaging operations more effective by simplifying customization and integration, which enables world class packaging operations. When implemented, packaging companies and their partners gain a competitive advantage as they leverage an integrated supply chain to optimize operations.

PackML/PackTags Technical Report Approved.

The ISA88 Committee has approved a new ISA88 Technical Report on Machine and Unit States. This technical report incorporates the OMAC Packaging Workgroup’s PackML and PackTags documents with the industry standard ISA88 terminology.

The ISA88 Committee has approved a new ISA88 Technical Report on Machine and Unit States. This technical report incorporates the OMAC Packaging Workgroup’s PackML and PackTags documents with the industry standard ISA88 terminology.

Technical overview

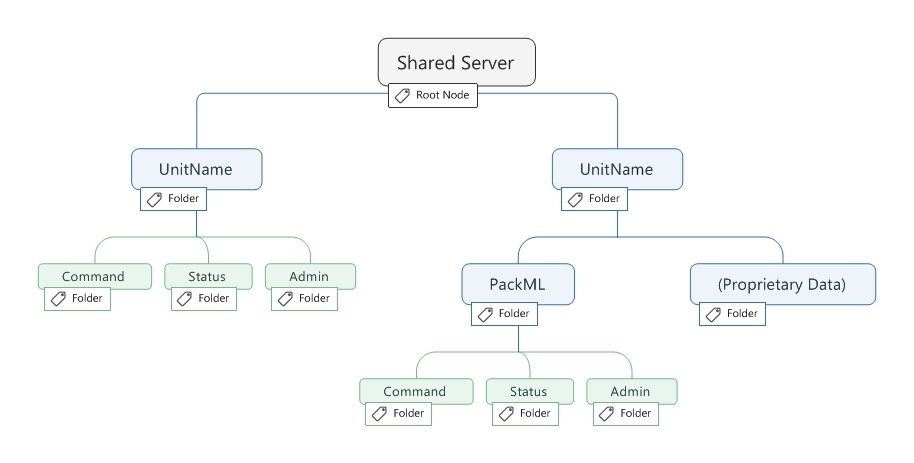

The ISA88 Technical Report (TR88.00.02) states: “PackTags are broken out into three groups; Command, Status and Administration. Command and Status tags contain data required for interfacing between machines and line control for coordination, or for recipe / parameter download. Command tags are “written” to and consumed by the machine program, as the “Information Receiver”, while status tags are produced by and read from the machine program. Administration Tags contain data collected by higher level systems for machine performance analysis, or operator information.”

Due to the clearly defined structure and datatypes of PackTags within the TR88 document, it is very ideal for combining the strength of PLCopen features and OPC UA structures in order to obtain standardized Machine-2-Machine communication or even communication to MES or ERP systems.

Companies behind

Technology suppliers:

• ABB

• AES Controls

• Apex

• Axcend

• B&R

• Beckhoff

• Bosch Rexroth

• COPA-DATA

• E Technology Group

• ei3

• Festo

• Keba

• L&T Technology

• Lenze

• LTI Motion

• Mitsubishi Electric

• Omron

• Patti Engineering

• Rockwell Automation

• Rovisys

• Sartorious

• Schneider Electric

• SeQuent

• SEW Eurodrive

• Sick

• Siemens

• SMC

• Spiroflow

• Yaskawa

• AES Controls

• Apex

• Axcend

• B&R

• Beckhoff

• Bosch Rexroth

• COPA-DATA

• E Technology Group

• ei3

• Festo

• Keba

• L&T Technology

• Lenze

• LTI Motion

• Mitsubishi Electric

• Omron

• Patti Engineering

• Rockwell Automation

• Rovisys

• Sartorious

• Schneider Electric

• SeQuent

• SEW Eurodrive

• Sick

• Siemens

• SMC

• Spiroflow

• Yaskawa

Endusers:

• Arla Foods

• Boeing

• Bosch

• Coesia

• Corning

• Eurosigma

• Fox IV Technologies

• GEA

• Harro Höfliger

• Mettler Toledo

• MillerCoors

• Meurer

• Nestlé

• PakTech

• Pepsico

• Pro Mach

• P&G

• SIG

• Smitec

• Boeing

• Bosch

• Coesia

• Corning

• Eurosigma

• Fox IV Technologies

• GEA

• Harro Höfliger

• Mettler Toledo

• MillerCoors

• Meurer

• Nestlé

• PakTech

• Pepsico

• Pro Mach

• P&G

• SIG

• Smitec

More Information

- http://omac.org/workgroups/packaging-workgroup/

- Contact: Chairman Uwe Keiter Uwe.Keiter[at]lenze.com

- 10min Video by Christian Hock, Siemens about OMAC & OPC UA: PackML standardization

About OMAC

In today’s global economy, manufacturers continue to strive for new ways to reduce delivery times, be more efficient with available resources, and increase profitability, all while maintaining their competitive advantage. When manufacturers come together and share best practices, the whole industry benefits. The Organization for Machine Automation and Control (OMAC) was formed to meet this purpose and help manufacturers work together to find new and innovative ways to be successful their production operations. OMAC brought together leading manufacturers representing End-User Manufacturers, OEM Machine Builders, System Integrators, Technology Providers, and Non-Profit / Government Agency organizations to address issues that confront global manufacturing today. OMAC’s two working groups, Packaging and Machine Tool, lead the way in producing industry consensus guidelines that help manufacturers reduce their delivery times, be more efficient with available resources, and increase profitability, all while maintaining their competitive advantage.