Scope / Goals

Develop specifications for Geometrical Measuring System (e. g. Manual and Automatic Gauging Systems for Dimensional Tasks, Coordinate Measuring Systems (including Multi-sensor Systems) and Machines, Form Measuring Systems, Surface Texture Measuring Systems) in various industries.

It enables the seamless integration of various measuring devices, from calipers to coordinate measuring systems, into the production environment.

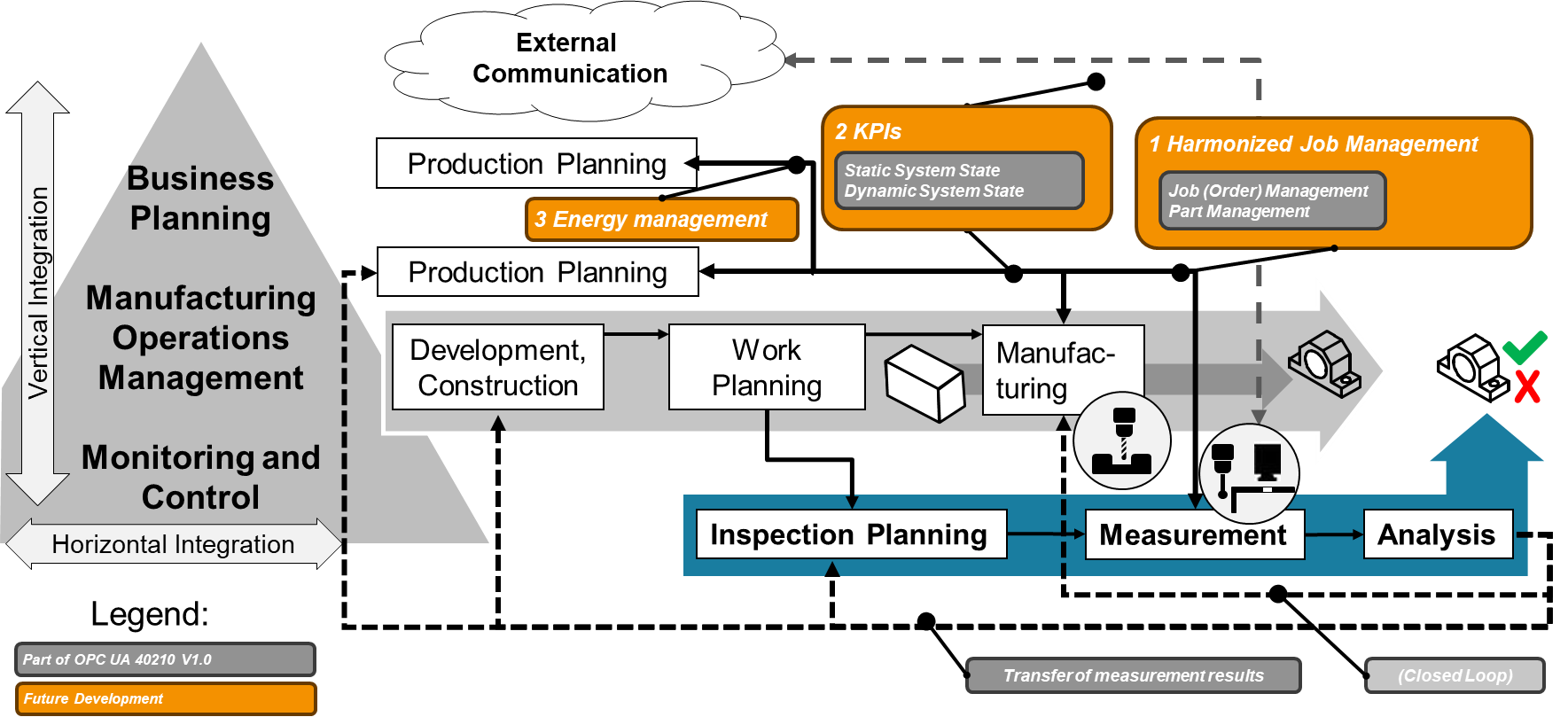

Among others, the following functionalities shall be covered:

- static machine data (identification of the GMS)

- dynamic machine data (current state/status of the GMS)

- job management (monitoring of measurement routines)

- parts data management (identification of parts and related information)

- measurement results (management of the provision of measurement results)

PLUG AND PLAY IN MEASUREMENT TECHNOLOGY

Innovations in measurement technology are increasingly linked to data. Standardized communication channels are required to organize the exchange of data from different machines efficiently and without errors. Manufacturers of measurement and testing technology rely on standards to integrate length measurement technology into the smart factory.

Perspectives

The standardization and uniform storage of the information enables plug and play, so that the coordinate measuring system automatically integrates into the digital production. This offers potential for the development of reusable and continuously expandable standard modules.

The energy management use case will be added to future releases. In addition, the job management use case will be harmonized with current developments from other companion specifications and the static and dynamic machine data will be expanded into a key figure system that allows conclusions to be drawn about the quality of the measured component and the quality of the measurement.