Scope / Goals

Develop specifications to represent tobacco industry machine information to higher-level manufacturing systems (MS/MOM) and to ease machine-to-machine communication.

Use Cases

The material flow serves as the foundation upon which various use cases are constructed, including:

- Monitoring and control: real-time standardized states for machine and remote control;

- Malfunctions: root-cause identification;

- Asset management: processing capability of machines and their digital history (through relocations, revamps);

- Production: real time reporting, full digital setup control, MES/MOM integration;

- Material tracking and integrity: from raw tobacco to finished sticks;

- Replenishment: material stock, consumption and just-in-time reorder;

- Rejects: real-time monitoring with defect data collection;

- Supervision: zero-touch supervision and control;

- Process Cell: orchestration of production units according to ISA95;

- Remote Control Loops: enabling advanced controls, e.g. AI, MPC, securely improve the control of the machine.

Technical Overview

In most tobacco factories the secondary machine communication landscape is highly fragmented, both for machine-to-machine and machine-to-higher systems data streams. The fragmentation is evident on many levels: physical media, protocols, data formats, sometimes proprietary, have added up over time with the machines. Unnecessarily high integration efforts result. Moreover, extracting manufacturing insights from the machine data is a valuable opportunity that is severely limited by the fragmentation.

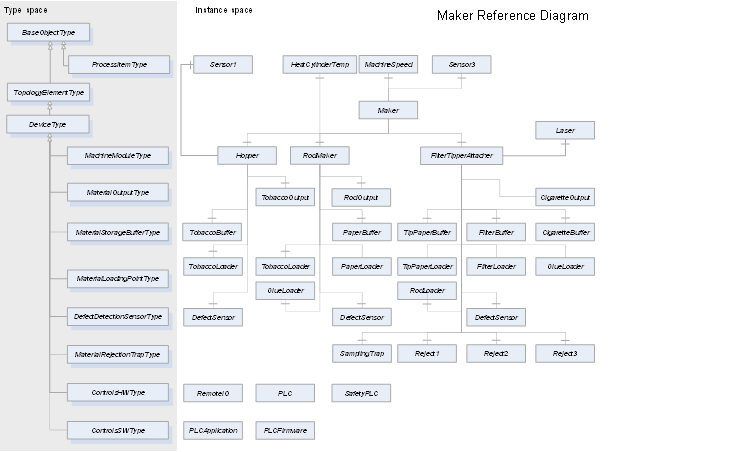

Main objective are information-modelling concepts and object libraries that can be applied to model a complete production workcentre. It covers machine configurations, product flows, production, set-up, service, live status as well as historical information.

The OPC UA server of the work center can expose information in a harmonized way to upper level systems or to compliant other work centers.

Background (Before TMC)

In most tobacco factories, the machine communication landscape is highly fragmented, both for machine-to-machine and machine-to-higher-level systems. This fragmentation is evident on various levels, including physical media, protocols, data formats, and even proprietary solutions for certain machines. The fragmentation poses technical limitations on the exposed information and practical limitations due to the excessive effort required to address it.

Current Status (With TMC)

The TMC specification has demonstrated its effectiveness in harmonizing data exposure and facilitating interoperability across all production areas, including primary and secondary, RRP, and conventional. Several manufacturers have developed data stacks that automatically retrieve standardized TMC OPC UA types to feed their digital initiatives.

Some tobacco manufacturers have retrofitted TMC OPC UA to legacy equipment, while for new equipment, it is mandated as the sole interface to higher-level systems, such as SCADA and MES/MOM. Major Original Equipment Manufacturers (OEMs) provide TMC OPC UA servers for new equipment. As of February 2025, independent estimates indicate that several hundred TMC OPC UA servers are currently operational.

Future of TMC

Extensions and improvements to the TMC specification, including support for AI/ML, are being considered.