Scope / Goals

Develop an OPC UA Information Model for laser systems. Such a system is considered a self-contained unit, including the laser source and all required subsystems, such as the control system for the laser source, optics, cooling aggregates and others. Hence, one or several laser systems may be a subcomponent of a larger machine. The goal of this companion specification is to provide a standardized and extendable interface for the integration of laser systems into an OPC UA environment. This interface shall then provide laser system maintainers with easy and robust access to information, based on which they can optimize their individual processes and derive additional value. One example would be the enabling of fast and target-oriented maintenance measures or the on-demand stock part management of service life parts. This is primarily achieved by providing data regarding the laser source system type, identity, and past and current states/conditions.

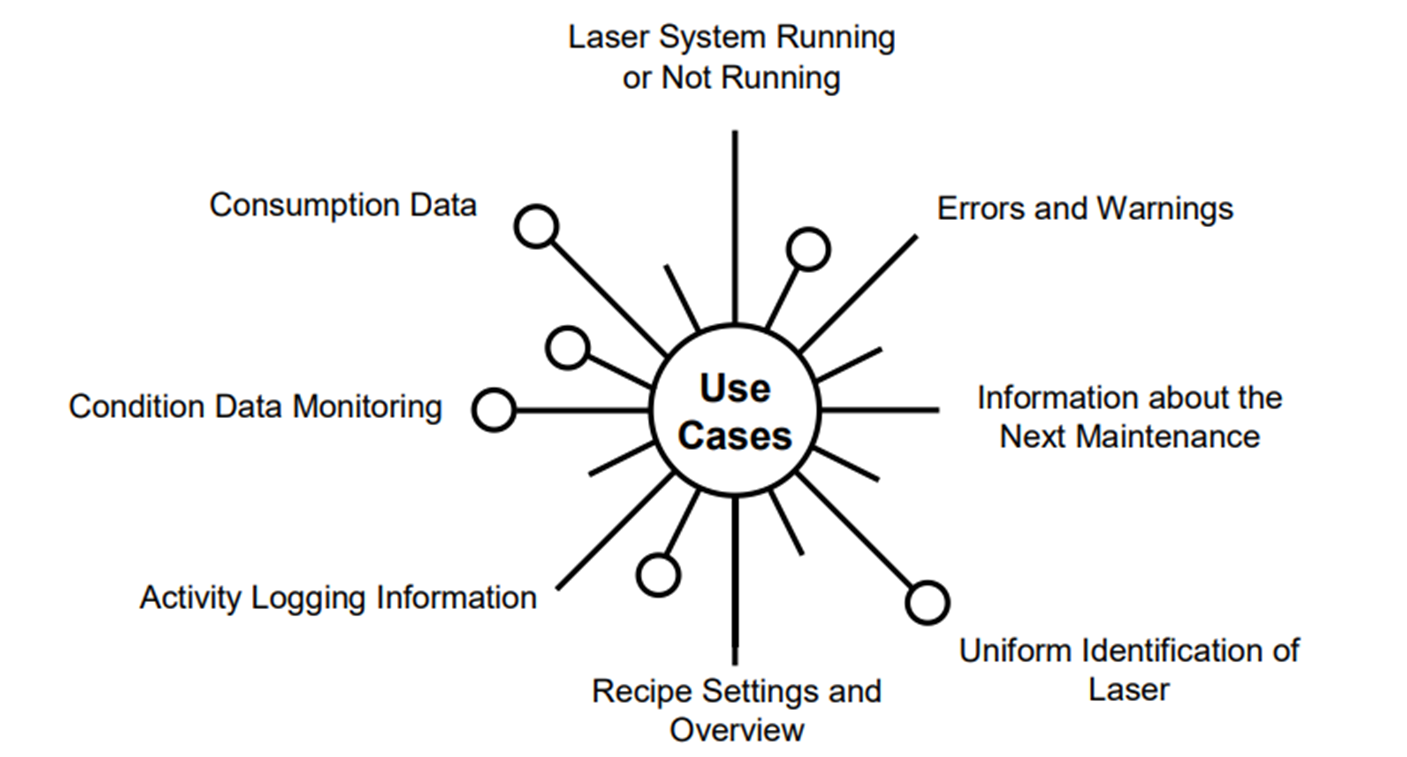

Use Cases

OPC UA for laser systems tackles the connectivity of the future by providing an easy, secure, and seamless open standard defining globally applicable semantics for laser systems. The standard reduces the effort for the connection of laser systems from various manufacturer with customer-specific IT infrastructures and ecosystems by simplifying the access interface using OPC UA.

The use cases describe possible usage scenarios of the interface and the added value that can be achieved. Other or additional applications not described in the mentioned use cases can be realized by using the provided parameters.

Fig 1: Use Cases for OPC UA Laser Systems

The following are the use cases covered in Version 1.0 published February 2024:

- Laser System Running or Not Running

- Errors and Warnings

- Information about the Next Maintenance

- Uniform Identification of Laser Systems

- Recipe Settings and Overview

- Activity Logging Information

- Condition Data Monitoring

- Consumption Data

The use cases are described from the view point of a maintainer. This does not exclude other possible roles, e.g. a production manager or machine operator, to make use of the interface.

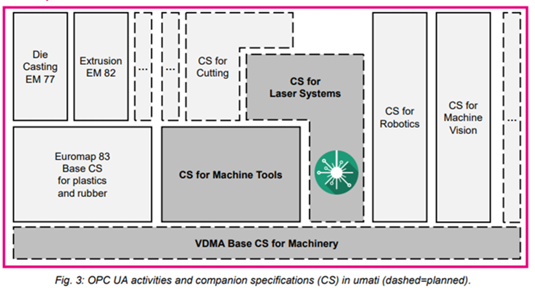

Relation to umati

The umati initiative is supported jointly by the VDW and the VDMA, the Mechanical Engineering Industry Association. Umati – the universal machine technology interface – enables machines and peripherals to connect to customer-specific IT ecosystems using OPC UA. The initiative is open to participants from industry, research, organisations and networks from all over the world.

Fig 2: OPC UA activities and Companion Specifications (CS) in umati

More Information

A workshop introduces the OPC UA information model for laser systems and presents use cases demonstrating added value, such as streamlined maintenance and efficient inventory management of service life parts: https://www.youtube.com/watch?v=umfcwWQn72Y