Sensor to Cloud Integration: FDT and OPC UA Pair for “The Connected World”

Overview

Since 2014, the FDT Group and OPC Foundation have worked together to provide greater access to critical information throughout the industrial enterprise. The FDT® standard is the hub of critical information from tens of millions of Device Type Manager™ (FDT/DTM™)-enabled devices installed in the field, while the OPC UA standard provides an infrastructure to make this information available to thousands of other applications and platforms.

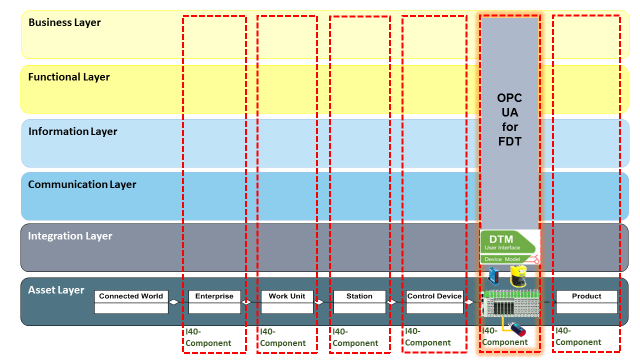

With the OPC UA for FDT companion specification for information modeling, intended for implementation by automation system manufacturers in FRAME Applications™ (FDT/FRAMEs™) embedded in Engineering Systems, Distributed Control Systems (DCSs), asset management systems and other applications, the FDT Group and OPC Foundation have taken an important step forward towards helping end users in the factory, hybrid and process automation markets realize the promise of the Industrial Internet of Things (IIoT) and Industrie 4.0 for the ”Connected World.”

Technical Description

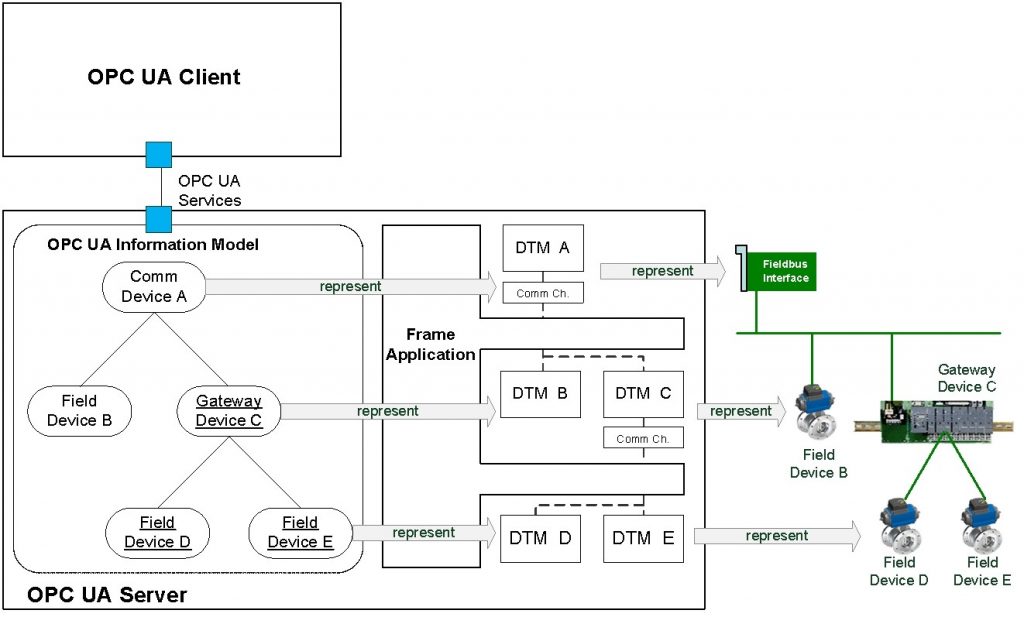

Interoperability is at the heart of the OPC UA using the FDT companion specification. The FDT standard sits at the intersection of the variety of networks attached to intelligent devices and the higher-level systems requiring interaction with the devices.

The FDT standard establishes an open, modular and holistic automation architecture that can adapt to the changing requirements of suppliers and end users. It incorporates a plant hierarchy based on the physical network topology coupled with a logical topology. FDT supports all major networks employed in process and factory automation, and will accommodate future networks as the industry demands. This approach makes it possible for an FDT/FRAME-enabled system to transparently tunnel through disparate networks to gain access to, and talk with any end device.

To advance its support of the IIoT and Industrie 4.0, FDT Group has developed a solution known as “FITS™” (FDT IIoT Server) enabling mobility, cloud, and fog enterprise applications, as well as sensor-to-cloud and enterprise-wide connectivity. This solution (essentially an FDT/FRAME™ deployed with FDT/OPC information modeling) employs FRAME and DTM business logic at the heart of its client-server architecture. The FRAME interface seamlessly enables operational lifecycle access to asset, commissioning, diagnostic, prognostic, and other higher-level data. To make these data sources available to the open OPC UA architecture, the data is mapped to the OPC UA information model to present it in a standardized fashion. The FDT/FRAME-enabled system can be configured like any other FRAME Application. OPC UA-based applications requiring access to information from an FDT/OPC UA server take on the characteristics of an OPC UA client. The client requests a secure connection with the FDT/OPC UA server and begins to access topology, device health and other data.

Leveraging a robust information model

Standard integration of information provided by FDT/DTMs into the OPC UA information model is essential for device diagnostics, configuration and remote asset management, as well for integration with Manufacturing Execution Systems (MES). The FDT/OPC UA information model enhances the management of networks and devices, helping to optimize the enterprise by giving access to data without the need for protocol-specific handling and providing support for a wide range of devices.

Providing a powerful integration solution

OPC provides a uniform interface for many different client applications, whereas FDT provides network/device configuration and access to devices. The combined FDT/OPC approach enables unification of system engineering, configuration and diagnosis in Industry 4.0, and supports Industry 4.0 devices, but is also able to build a bridge to Industry 3.0 networks and devices.

The FDT standard is represented in the German Reference Architecture Model Industrie 4.0 (RAMI 4.0) as the device integration solution, and with the FDT/OPC companion specification, sensor-to-cloud, enterprise-wide connectivity is granted with seamless data communications.

More Information

- Download the FDT/OPC UA Information Model Specification at: http://fdtgroup.org/development/specifications/

- Contact the FDT Business Office for more information: info@fdtgroup.org

About FDT Group

The FDT Group AISBL is an international non-profit corporation consisting of leading worldwide member companies active in industrial automation and manufacturing. The major purpose of the FDT Group is to provide an open standard for enterprise-wide network and asset integration, innovating the way automation architectures connect and communicate sensor to cloud for the process, hybrid and factory automation markets. FDT Technology benefits both manufacturers and end users, with advancements such as the IIoT and Industrie 4.0 delivered out-of-the-box – enabling modernized asset integration and access to performance data for visualizing crucial operational problems. Around the world, end users, manufacturers, universities, and research organizations are working together to develop the technology; provide development tools, support, and training; coordinate field trials and demonstrations; and enable product interoperability.

Web FDT Group http://fdtgroup.org