Machine communication:

Integrated networking with Sercos and OPC UA

Overview

The OPC Foundation and Sercos International have started their collaboration in 2011 with the common aim to improve the machine integration and to reduce the complexity of information exchange between machine periphery and higher-level IT systems. The chosen approach is a standardized OPC UA Sercos information model that brings together the well-defined device profiles of Sercos with the data exchange standard of OPC UA. The OPC UA companion specification for Sercos describes the mapping of Sercos to OPC UA so that the functionality of Sercos devices is made available and accessible via OPC UA in a vendor-independent way. The access to process and machine related information facilitates the efficient and flexible use of the manufacturing resources which is also a key target of Industry 4.0. Application scenarios cover a broad range from device parametrization and network configuration up to energy management and preventive maintenance.

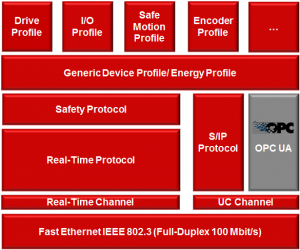

Sercos is one of the world’s leading digital interfaces for communication between controls, drives, I/Os and other decentralized peripheral devices, such as encoders, safety devices and vision systems. Since its first release in 1990, Sercos has been further developed from a digital drive interface into a universal automation bus. The third generation of Sercos is based on Ethernet and is in particular suitable for high-speed and high-precision machining applications. Because of its universal approach that includes motion, safety and I/O capabilities, it can be used for all kind of automation applications. A special feature is the so-called Unified Communication (UC) channel which allows the transmission of additional Ethernet protocols, such as TCP/IP or EtherNet/IP over a common network infrastructure (see Figure 1). The UC channel therefore can also be used to communicate using the common standard OPC UA.

TYPICAL USE-CASES INCLUDE

- Visualization: Providing information for human-machine interfaces or operator panels.

- Monitoring: Providing information for energy, condition and process monitoring, network status.

- Diagnosis: Providing context-sensitive diagnosis information for operators and service personnel.

- Engineering: Device parameter browsing, device parametrization, controller optimization, network configuration

ADVANTAGES

The specified Sercos OPC UA mapping allows the access to the device information model, based on the defined Sercos profiles. Sercos device suppliers & users find ready-to-use methods, tools and applications to make available machine and process data to higher-level systems. On the other hand, manufacturers of IT systems (including MES/ ERP and SCADA software) are able to directly access the available information without the need for vendor-specific interpretations or conversions. The best of both worlds combination shows a migration to Industry 4.0, allowing to connect each and every existing Sercos-based device, with very low efforts!

Technical content

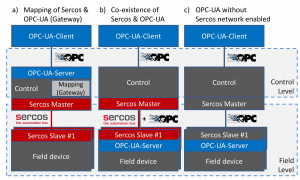

The specified OPC UA mapping for Sercos is based on an extension of an OPC UA server. Therefore, it can be used for different implementation approaches (see figure 2).

- The OPC UA server functionality can be implemented in a Sercos master device (e.g. CNC or PLC). This device is acting as a gateway to map the OPC UA accesses to Sercos services and vice versa (Option a). Access to the Sercos parameters in a Sercos slave device is provided by cyclic and acyclic services of the Sercos real-time channel, or by means of the S/IP protocol which provides IP-based access to all Sercos parameters even the Sercos real-time communication is not enabled (Option 2a).

- The OPC UA server functionality can also be implemented in a Sercos slave device. In this case, the OPC UA protocol is transmitted in the so-called Unified Communication (UC) channel of Sercos which is available in parallel to the Sercos real-time communication (option 2b) and even in the case that the Sercos real-time communication is not enabled (option 2c).

The Sercos OPC UA companion specification describes the mapping of data types between OPC UA and Sercos, as well as the transformation of the Sercos data model (consisting of profiles, classes, function groups and the supported parameters) into the OPC UA information model. By this, standardized access to the information of a Sercos field device is given

Companies behind

The following companies have actively contributed to the OPC UA companion specification on behalf of the members of Sercos International and all users of the Sercos technology:

- Bosch Rexroth

- ESR Pollmeier

- FISW Steuerungstechnik GmbH

- Schneider Electric

- Softing

More Information: specification, video, flyer

- Download here:The Sercos OPC UA companion specification Version 1.0

- See here: Video “Sercos and OPC UA” by Peter Lutz, Managing Director Sercos International

- Download here: Flyer : “Machine communication – Integrated networking with Sercos and OPC UA”

About Sercos International

Sercos International is an association of users and manufacturers that is in charge of technical development, standardization, certification and marketing for the Sercos automation bus. Conformance tests guarantee that Sercos implementations are standard-compliant ensuring that devices from different manufacturers can be combined. Based in Germany, the organization presently has more than 90 member companies located around the world and has national liaison offices in North America and Asia.

Contact information

Sercos International e.V.

Kreuzstr 38

97837 Erlenbach, Germany

www.sercos.org

Klaus Weyer k.weyer@sercos.de