umati – universal machine tool interface

OPC UA Companion Specification for machine tools and manufacturing systems to external communication partners

Overview

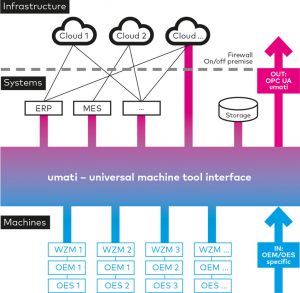

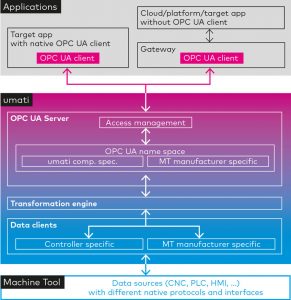

The joint OPC UA working group “umati JWG” will be established between VDW, the German machine tool builders’ association, and the OPC Foundation. Its purpose is to develop an OPC UA Information Model for a universal communication interface of machine tools towards “external” communication partners, e.g. MES, ERP, cloud, automation system etc…

The label “umati” ‘(universal machine tool interface) was established by VDW during a preliminary project, “Connectivity for Industry 4.0“, which originated in 2017 and led to the development of a draft standardized information model which serves as the input for discussion in the umati JWG.

In the field of CNC machine tools, there is a multitude of communication interfaces, profiles and mechanisms for the integration of machine tools into a production network. There are standardized as well as manufacturer-specific solutions to be found. This variety just like the lacking consistency of the standardization currently lead to considerable effort in the case of system networking.

The working group for the preliminary project consists of 17 partners, which are listed below, and includes major machine tool builders of Germany and Switzerland, as well as leading CNC control manufactures.

This group presented a proof of concept with a showcase at the AMB 2018 trade fair Stuttgart in September of 2018. At least one machine of each partner was connected via an OPC UA information model draft with 12 parameters. The implementation took between 8 and 16 hours, with the assistance of the respective controls supplier to get the OPC UA Server configured and ready for sending data to a demo MES system.

We now invite every interested party to join the joint working group, to make this a global standard for machine tool connectivity.

Project schedule

Preparatory work has been done by the aforementioned project working group. The results of this work will be provided as an advanced starting point for the Joint Working Group.

- December 2018 Call for members

- January 2019 Distribution of working draft of the preparatory work to registered participants (Electronic pre-kick-off meeting with information about the umati information model – prepared by core working group)

- February 2019 Kick-off meeting with discussion of the proposed model

- March 2019 Review of release candidate proposal

- April 2019 Processing of review comments into publication of release candidate by the core working group for umati OPC UA information model

The following dates are planned and can be adjusted by the working group. The working group may also add additional milestones, such as shows for presentation on the mapping. - February 2019 Internal first draft for umati specification

- April 2019 Release Candidate version of the umati information model

Technical content

What is the object of standardization:

- Parameter definition by use cases (follows OPC UA best practice) – the following list shows the use cases which have been collected during the preliminary work. The first draft of the CS, however, will consider a reduced set only:

Fast overview if production is running - Overview machine and job Status

- Job overview

- Overview of Errors

- State of operation (time line representation)

- Show alerts / warnings / interruptions

- Statistics of ressource consumption

- unified identification of machines of various suppliers /

overview of complete installed machine base - Information about upcoming manual Intervention

- TPM measures

- State of Machine

- Statistics of program run time

- Statistics of program occurence

- Statistics of down-time and -reasons

- OEE-Analysis

- Job Order

- Statistics of consumption (2)

- OEE-Analysis (2)

- Tool Management

- Read/Write Tool and Job Data

- State of operations (sum)

Current status: 100+ parameters, 20+ use cases as input into

OPC UA information modelling procedure

Preliminary project group

• CHRION

• DMG MORI

• EMAG

• GF Machining Solutions

• GROB-WERKE

• HELLER

• Liebherr-Verzahntechnik

• Pfiffner

• TRUMPF

• UNITED GRINDING Group

• Beckhoff

• Fanuc

• Heidenhain

• Rexroth

• Siemens

• ISW – University Stuttgart

• VDW

Call for members:

Please get in contact if you like to join the working group.

About

More Information

• umati insights presentation – see here:

• Visit the initiative website at: https://www.umati.info

Contact

Chair project group: Götz Görisch

Contact information VDW e.V.